![]() Tel:+86 0532 89922862

Tel:+86 0532 89922862

![]() Email: sales@seakongmarine.com

Email: sales@seakongmarine.com

Product Details

Wire Rope Carpenter Stoppers

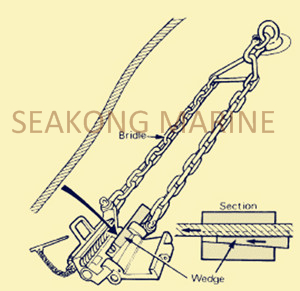

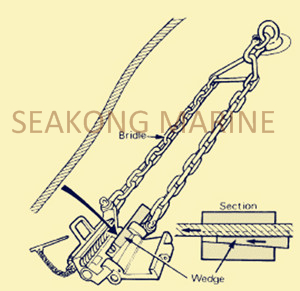

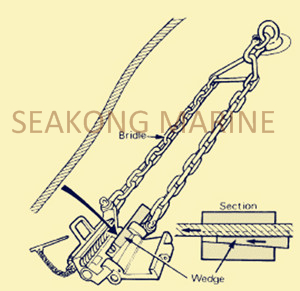

Carpenter Stoppers are sliding wedge block wire rope stoppers that hold wire wope without damage up to breaking strength or without any personal injury, popularly used as safety gears for salvage field.

Normally, the Carpenter Stoppers consist of a two-sided wedge inside a housing, the wire rope fit between the two sides of the wedge so that rope tension force the wedge tightly into the housing,the wire rope can be removed under tension by releasing the latch on the hinged lid.

Our Carpenter Stoppers are designed to be equal breaking load of matched wire rope which is accordance to OCIMF rules and Navy Specifications.

For safety factor, our carpenter stoppers are proof loaded to double the safe working load of the wire rope or cable being used.

Based on durable and rugged design, all bodies and wedges are precisely casted from high quality carbon steel and all pins are made from high strength alloy steel.

We have the ability to manufacture two movable sides wedge, or one side fixed and the other movable for you on request.

Our supply range is to suit wire rope from 12mm to 90mm although larger capacity units can be manufactured.

Hualing Wire,Chain Bridle, Traveling Block, Ground Leg can be supplied together.

MAIN FEATURES

• Compact and Lightweight design for one man operation

• Self-tightening and can be left unattended

• Suit for Dia. 12mm-90mm R.H.L 6 strand wire rope, large size on request

• Each wire size requires a different carpenter stopper

• Offer from SWL5T to SWL100T

• Proof Load=2 X SWL

• Breaking load is equal to Wire MBL

• 100% tested and ABS 3rd party inspection certified

• Hualing Wire,Chain Bridle, Traveling Block, Ground Leg can be supplied together

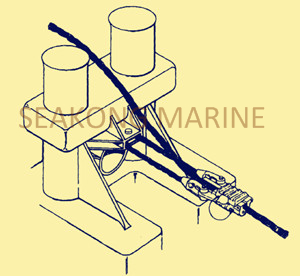

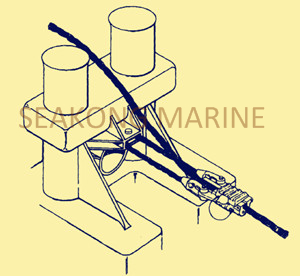

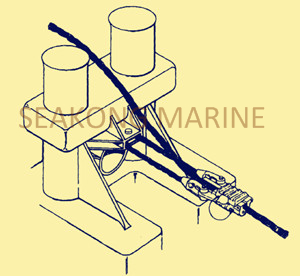

WHERE TO USE CARPENTER STOPPER ? See below

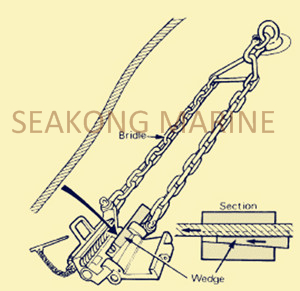

HOW TO ACCEMBLE CARPENTER STOPPER ? See below

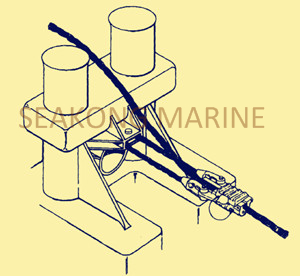

HOW TO OPERATE CARPENTER STOPPER ? See below

Carpenter Stoppers are sliding wedge block wire rope stoppers that hold wire wope without damage up to breaking strength or without any personal injury, popularly used as safety gears for salvage field.

Normally, the Carpenter Stoppers consist of a two-sided wedge inside a housing, the wire rope fit between the two sides of the wedge so that rope tension force the wedge tightly into the housing,the wire rope can be removed under tension by releasing the latch on the hinged lid.

Our Carpenter Stoppers are designed to be equal breaking load of matched wire rope which is accordance to OCIMF rules and Navy Specifications.

For safety factor, our carpenter stoppers are proof loaded to double the safe working load of the wire rope or cable being used.

Based on durable and rugged design, all bodies and wedges are precisely casted from high quality carbon steel and all pins are made from high strength alloy steel.

We have the ability to manufacture two movable sides wedge, or one side fixed and the other movable for you on request.

Our supply range is to suit wire rope from 12mm to 90mm although larger capacity units can be manufactured.

Hualing Wire,Chain Bridle, Traveling Block, Ground Leg can be supplied together.

MAIN FEATURES

• Compact and Lightweight design for one man operation

• Self-tightening and can be left unattended

• Suit for Dia. 12mm-90mm R.H.L 6 strand wire rope, large size on request

• Each wire size requires a different carpenter stopper

• Offer from SWL5T to SWL100T

• Proof Load=2 X SWL

• Breaking load is equal to Wire MBL

• 100% tested and ABS 3rd party inspection certified

• Hualing Wire,Chain Bridle, Traveling Block, Ground Leg can be supplied together

WHERE TO USE CARPENTER STOPPER ? See below

HOW TO ACCEMBLE CARPENTER STOPPER ? See below

HOW TO OPERATE CARPENTER STOPPER ? See below

1. Open the stopper bodies.

2. Loose the Spike drawer set screw. Fix the shackles with dead end or strongpoint by chain bridle or rope bridle.

3. Grease the spoke drawer for sliding easy and rusting protection.

4. Place the spike small end on the middle of the stopper bodies.

5. Lay the rope on the spike drawer.

6. Close the bodies with the U-Hinge and lock pin

7. Pre-tension the stopper slowly and hammer the spike drawer to tighten the rope.

8. The spike drawer slides in the stopper to tight the rope in tension.

9. Stand clear and away the stopper and towing line while in tension.

10. The stopper would seized the rope in full tension.

10. The stopper would seized the rope in full tension.

11. Cable can be released under full tension by releasing the keeping plate and U-Hinge.

12. Fix the spike drawer with the set screw for stand-by condition to prevent loosen.

13. Always grease the hinge and drawer for maintenance.

HOW ABOUT OUR QUALITY CONTROL? See below

HOW ABOUT OUR QUALITY CONTROL? See below

We're the the most professional company for Carpenter Stopper in China mainland !

All Carpenter Stoppers are 100% load tested

All Carpenter Stoppers are 100% load tested

Contact Us Now

Product Details

Wire Rope Carpenter Stoppers

Carpenter Stoppers are sliding wedge block wire rope stoppers that hold wire wope without damage up to breaking strength or without any personal injury, popularly used as safety gears for salvage field.

Normally, the Carpenter Stoppers consist of a two-sided wedge inside a housing, the wire rope fit between the two sides of the wedge so that rope tension force the wedge tightly into the housing,the wire rope can be removed under tension by releasing the latch on the hinged lid.

Our Carpenter Stoppers are designed to be equal breaking load of matched wire rope which is accordance to OCIMF rules and Navy Specifications.

For safety factor, our carpenter stoppers are proof loaded to double the safe working load of the wire rope or cable being used.

Based on durable and rugged design, all bodies and wedges are precisely casted from high quality carbon steel and all pins are made from high strength alloy steel.

We have the ability to manufacture two movable sides wedge, or one side fixed and the other movable for you on request.

Our supply range is to suit wire rope from 12mm to 90mm although larger capacity units can be manufactured.

Hualing Wire,Chain Bridle, Traveling Block, Ground Leg can be supplied together.

MAIN FEATURES

• Compact and Lightweight design for one man operation

• Self-tightening and can be left unattended

• Suit for Dia. 12mm-90mm R.H.L 6 strand wire rope, large size on request

• Each wire size requires a different carpenter stopper

• Offer from SWL5T to SWL100T

• Proof Load=2 X SWL

• Breaking load is equal to Wire MBL

• 100% tested and ABS 3rd party inspection certified

• Hualing Wire,Chain Bridle, Traveling Block, Ground Leg can be supplied together

WHERE TO USE CARPENTER STOPPER ? See below

HOW TO ACCEMBLE CARPENTER STOPPER ? See below

HOW TO OPERATE CARPENTER STOPPER ? See below

Carpenter Stoppers are sliding wedge block wire rope stoppers that hold wire wope without damage up to breaking strength or without any personal injury, popularly used as safety gears for salvage field.

Normally, the Carpenter Stoppers consist of a two-sided wedge inside a housing, the wire rope fit between the two sides of the wedge so that rope tension force the wedge tightly into the housing,the wire rope can be removed under tension by releasing the latch on the hinged lid.

Our Carpenter Stoppers are designed to be equal breaking load of matched wire rope which is accordance to OCIMF rules and Navy Specifications.

For safety factor, our carpenter stoppers are proof loaded to double the safe working load of the wire rope or cable being used.

Based on durable and rugged design, all bodies and wedges are precisely casted from high quality carbon steel and all pins are made from high strength alloy steel.

We have the ability to manufacture two movable sides wedge, or one side fixed and the other movable for you on request.

Our supply range is to suit wire rope from 12mm to 90mm although larger capacity units can be manufactured.

Hualing Wire,Chain Bridle, Traveling Block, Ground Leg can be supplied together.

MAIN FEATURES

• Compact and Lightweight design for one man operation

• Self-tightening and can be left unattended

• Suit for Dia. 12mm-90mm R.H.L 6 strand wire rope, large size on request

• Each wire size requires a different carpenter stopper

• Offer from SWL5T to SWL100T

• Proof Load=2 X SWL

• Breaking load is equal to Wire MBL

• 100% tested and ABS 3rd party inspection certified

• Hualing Wire,Chain Bridle, Traveling Block, Ground Leg can be supplied together

WHERE TO USE CARPENTER STOPPER ? See below

HOW TO ACCEMBLE CARPENTER STOPPER ? See below

HOW TO OPERATE CARPENTER STOPPER ? See below

1. Open the stopper bodies.

2. Loose the Spike drawer set screw. Fix the shackles with dead end or strongpoint by chain bridle or rope bridle.

3. Grease the spoke drawer for sliding easy and rusting protection.

4. Place the spike small end on the middle of the stopper bodies.

5. Lay the rope on the spike drawer.

6. Close the bodies with the U-Hinge and lock pin

7. Pre-tension the stopper slowly and hammer the spike drawer to tighten the rope.

8. The spike drawer slides in the stopper to tight the rope in tension.

9. Stand clear and away the stopper and towing line while in tension.

10. The stopper would seized the rope in full tension.

10. The stopper would seized the rope in full tension.

11. Cable can be released under full tension by releasing the keeping plate and U-Hinge.

12. Fix the spike drawer with the set screw for stand-by condition to prevent loosen.

13. Always grease the hinge and drawer for maintenance.

HOW ABOUT OUR QUALITY CONTROL? See below

HOW ABOUT OUR QUALITY CONTROL? See below

We're the the most professional company for Carpenter Stopper in China mainland !

All Carpenter Stoppers are 100% load tested

All Carpenter Stoppers are 100% load tested

Contact Us Now:

-

ABOUT US

-

PRODUCT

-

NEWS

-

CONTACT US

ADDRESS:No.19 Qutangxia Road, Shinan District,Qingdao City,China

TELEPHONE:+86 0532 89922862

E-MAIL:sales@seakongmarine.com

NEWS

CONTACT US

ADDRESS:No.19 Qutangxia Road, Shinan District,Qingdao City,China

TELEPHONE:+86 0532 89922862

E-MAIL:sales@seakongmarine.com