![]() Tel:+86 0532 89922862

Tel:+86 0532 89922862

![]() Email: sales@seakongmarine.com

Email: sales@seakongmarine.com

Product Details

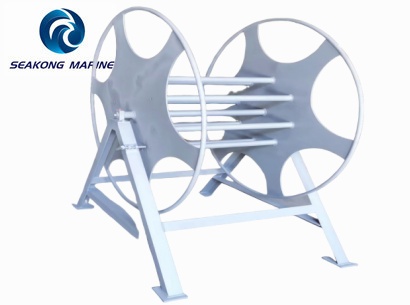

Cable Lifter

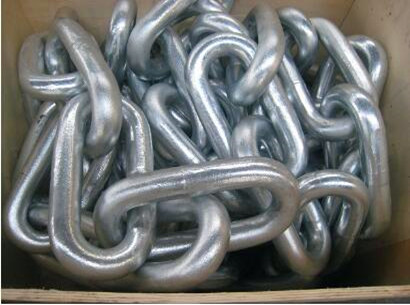

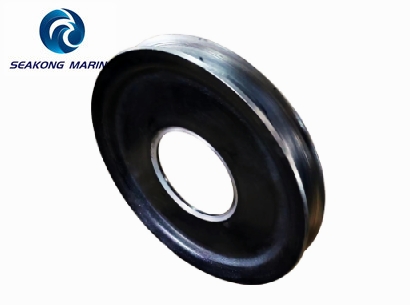

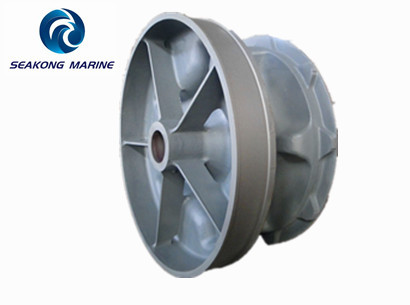

Cable Lifter ( also known as Chain Gypsy, Gypsy Wheel or Cable Holder) is a drum with deep grooves engaged with chain link,have Type A and Type B as per the number of teeth.

Type A is Five Teeth Cable Lifter, Type B is Six Teeth Cable Lifter.

It's the main part of the mooring machinery, its manufacturing quality directly affects the mooring and anchoring efficiency, which is very important to ensure the safe navigation of ships.

The meshing parts of the chain wheel and chain bear torque, traction and impact from all directions so request the quality to be high and strict.

Qingdao Seakong Marine Machinery Co., Ltd supplies Cable Lifter in size of 76mm,87mm,90mm,92mm,100mm,102mm,111mm,122mm etc,DNV,LR,ABS,BV Certs are all on request.

We controls the quality of Cable Lifter as below basic points

1.Adopt different contractibility rate: radial 1.4%, height 1.8%

2.Select suitable machining allowance,normally upper plane 18mm, underneath& side 14mm, hole 18mm

3.Due to the special structure of the casting, it is seriously blocked during shrinkage. Therefore, add 5 mm between the two sides for correction to ensure the size and strength requirements.

(The amount of technological compensation is set to make up for the fact that the casting wall thickness cannot meet the requirements due to the inconsistency of casting shrinkage and casting deformation.)

4.The upper and lower parts of the Cable Lifter are in the process of solidification and contraction, which easily lead to uneven stress and enlarged opening. In order to prevent deformation and lead to out-of-tolerance size, multiple tendons are set in the neutral place to increase the strength.

5. By simulating the casting, the hot spot position and the number of risers are determined.The effective feeding distance and feeding range of risers are calculated according to the section size of steel castings, temperature of molten steel and alloy composition.The center flange is provided with subsidy by using the spheroidal method, and additional feeding channel is added to eliminate the shrinkage hole of the lower hot node.In order to improve the feeding capacity of the riser, an insulating riser sleeve is adopted. After pouring, an insulating covering agent of sufficient thickness is arranged on the riser liquid surface to ensure uniform covering, reduce the cooling rate of the molten steel in the riser, and delay the solidification of the feeding part of the riser, so that the molten metal in the riser can replenish the casting and make the casting denser.

6. Due to the particularity structure of the Cable Lifter, various measures must be taken to ensure that the sequence of solidification, to ensure dense internal structure.The middle section of the chain wheel has a thin and long wall.Design with shape hanging outside the sand cold iron, adjust the shrinkage area, improve the temperature field, so that local forced solidification, but also to prevent structural sticking sand.

Cable Lifter ( also known as Chain Gypsy, Gypsy Wheel or Cable Holder) is a drum with deep grooves engaged with chain link,have Type A and Type B as per the number of teeth.

Type A is Five Teeth Cable Lifter, Type B is Six Teeth Cable Lifter.

It's the main part of the mooring machinery, its manufacturing quality directly affects the mooring and anchoring efficiency, which is very important to ensure the safe navigation of ships.

The meshing parts of the chain wheel and chain bear torque, traction and impact from all directions so request the quality to be high and strict.

Qingdao Seakong Marine Machinery Co., Ltd supplies Cable Lifter in size of 76mm,87mm,90mm,92mm,100mm,102mm,111mm,122mm etc,DNV,LR,ABS,BV Certs are all on request.

We controls the quality of Cable Lifter as below basic points

1.Adopt different contractibility rate: radial 1.4%, height 1.8%

2.Select suitable machining allowance,normally upper plane 18mm, underneath& side 14mm, hole 18mm

3.Due to the special structure of the casting, it is seriously blocked during shrinkage. Therefore, add 5 mm between the two sides for correction to ensure the size and strength requirements.

(The amount of technological compensation is set to make up for the fact that the casting wall thickness cannot meet the requirements due to the inconsistency of casting shrinkage and casting deformation.)

4.The upper and lower parts of the Cable Lifter are in the process of solidification and contraction, which easily lead to uneven stress and enlarged opening. In order to prevent deformation and lead to out-of-tolerance size, multiple tendons are set in the neutral place to increase the strength.

5. By simulating the casting, the hot spot position and the number of risers are determined.The effective feeding distance and feeding range of risers are calculated according to the section size of steel castings, temperature of molten steel and alloy composition.The center flange is provided with subsidy by using the spheroidal method, and additional feeding channel is added to eliminate the shrinkage hole of the lower hot node.In order to improve the feeding capacity of the riser, an insulating riser sleeve is adopted. After pouring, an insulating covering agent of sufficient thickness is arranged on the riser liquid surface to ensure uniform covering, reduce the cooling rate of the molten steel in the riser, and delay the solidification of the feeding part of the riser, so that the molten metal in the riser can replenish the casting and make the casting denser.

6. Due to the particularity structure of the Cable Lifter, various measures must be taken to ensure that the sequence of solidification, to ensure dense internal structure.The middle section of the chain wheel has a thin and long wall.Design with shape hanging outside the sand cold iron, adjust the shrinkage area, improve the temperature field, so that local forced solidification, but also to prevent structural sticking sand.

Contact Us Now

Product Details

Cable Lifter

Cable Lifter ( also known as Chain Gypsy, Gypsy Wheel or Cable Holder) is a drum with deep grooves engaged with chain link,have Type A and Type B as per the number of teeth.

Type A is Five Teeth Cable Lifter, Type B is Six Teeth Cable Lifter.

It's the main part of the mooring machinery, its manufacturing quality directly affects the mooring and anchoring efficiency, which is very important to ensure the safe navigation of ships.

The meshing parts of the chain wheel and chain bear torque, traction and impact from all directions so request the quality to be high and strict.

Qingdao Seakong Marine Machinery Co., Ltd supplies Cable Lifter in size of 76mm,87mm,90mm,92mm,100mm,102mm,111mm,122mm etc,DNV,LR,ABS,BV Certs are all on request.

We controls the quality of Cable Lifter as below basic points

1.Adopt different contractibility rate: radial 1.4%, height 1.8%

2.Select suitable machining allowance,normally upper plane 18mm, underneath& side 14mm, hole 18mm

3.Due to the special structure of the casting, it is seriously blocked during shrinkage. Therefore, add 5 mm between the two sides for correction to ensure the size and strength requirements.

(The amount of technological compensation is set to make up for the fact that the casting wall thickness cannot meet the requirements due to the inconsistency of casting shrinkage and casting deformation.)

4.The upper and lower parts of the Cable Lifter are in the process of solidification and contraction, which easily lead to uneven stress and enlarged opening. In order to prevent deformation and lead to out-of-tolerance size, multiple tendons are set in the neutral place to increase the strength.

5. By simulating the casting, the hot spot position and the number of risers are determined.The effective feeding distance and feeding range of risers are calculated according to the section size of steel castings, temperature of molten steel and alloy composition.The center flange is provided with subsidy by using the spheroidal method, and additional feeding channel is added to eliminate the shrinkage hole of the lower hot node.In order to improve the feeding capacity of the riser, an insulating riser sleeve is adopted. After pouring, an insulating covering agent of sufficient thickness is arranged on the riser liquid surface to ensure uniform covering, reduce the cooling rate of the molten steel in the riser, and delay the solidification of the feeding part of the riser, so that the molten metal in the riser can replenish the casting and make the casting denser.

6. Due to the particularity structure of the Cable Lifter, various measures must be taken to ensure that the sequence of solidification, to ensure dense internal structure.The middle section of the chain wheel has a thin and long wall.Design with shape hanging outside the sand cold iron, adjust the shrinkage area, improve the temperature field, so that local forced solidification, but also to prevent structural sticking sand.

Cable Lifter ( also known as Chain Gypsy, Gypsy Wheel or Cable Holder) is a drum with deep grooves engaged with chain link,have Type A and Type B as per the number of teeth.

Type A is Five Teeth Cable Lifter, Type B is Six Teeth Cable Lifter.

It's the main part of the mooring machinery, its manufacturing quality directly affects the mooring and anchoring efficiency, which is very important to ensure the safe navigation of ships.

The meshing parts of the chain wheel and chain bear torque, traction and impact from all directions so request the quality to be high and strict.

Qingdao Seakong Marine Machinery Co., Ltd supplies Cable Lifter in size of 76mm,87mm,90mm,92mm,100mm,102mm,111mm,122mm etc,DNV,LR,ABS,BV Certs are all on request.

We controls the quality of Cable Lifter as below basic points

1.Adopt different contractibility rate: radial 1.4%, height 1.8%

2.Select suitable machining allowance,normally upper plane 18mm, underneath& side 14mm, hole 18mm

3.Due to the special structure of the casting, it is seriously blocked during shrinkage. Therefore, add 5 mm between the two sides for correction to ensure the size and strength requirements.

(The amount of technological compensation is set to make up for the fact that the casting wall thickness cannot meet the requirements due to the inconsistency of casting shrinkage and casting deformation.)

4.The upper and lower parts of the Cable Lifter are in the process of solidification and contraction, which easily lead to uneven stress and enlarged opening. In order to prevent deformation and lead to out-of-tolerance size, multiple tendons are set in the neutral place to increase the strength.

5. By simulating the casting, the hot spot position and the number of risers are determined.The effective feeding distance and feeding range of risers are calculated according to the section size of steel castings, temperature of molten steel and alloy composition.The center flange is provided with subsidy by using the spheroidal method, and additional feeding channel is added to eliminate the shrinkage hole of the lower hot node.In order to improve the feeding capacity of the riser, an insulating riser sleeve is adopted. After pouring, an insulating covering agent of sufficient thickness is arranged on the riser liquid surface to ensure uniform covering, reduce the cooling rate of the molten steel in the riser, and delay the solidification of the feeding part of the riser, so that the molten metal in the riser can replenish the casting and make the casting denser.

6. Due to the particularity structure of the Cable Lifter, various measures must be taken to ensure that the sequence of solidification, to ensure dense internal structure.The middle section of the chain wheel has a thin and long wall.Design with shape hanging outside the sand cold iron, adjust the shrinkage area, improve the temperature field, so that local forced solidification, but also to prevent structural sticking sand.

Contact Us Now:

-

ABOUT US

-

PRODUCT

-

NEWS

-

CONTACT US

ADDRESS:No.19 Qutangxia Road, Shinan District,Qingdao City,China

TELEPHONE:+86 0532 89922862

E-MAIL:sales@seakongmarine.com

NEWS

CONTACT US

ADDRESS:No.19 Qutangxia Road, Shinan District,Qingdao City,China

TELEPHONE:+86 0532 89922862

E-MAIL:sales@seakongmarine.com

.jpg)