![]() Tel:+86 0532 89922862

Tel:+86 0532 89922862

![]() Email: sales@seakongmarine.com

Email: sales@seakongmarine.com

Product Details

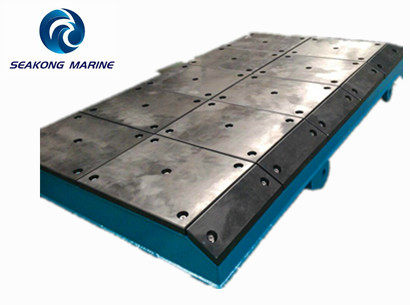

Fender Facing Panels

Welded from high quality plates and beams, the Fender Panels(also known as Frontal Frame) are fitted front of fender,to increase the contacting area,reduce fender surface pressure to ship when the ships berth.

UHME PE face plate on the top of fender panel which has very small friction coefficient less than 0.12,greatly reduce the friction, molecular weight on request.

Steel structures are designed on basis of finite element analysis by our veteran engineer team,ensure the strength and life time.

All welds are to be full penetration butt welds, all fillet welds to be continuous,all exposed steel below MLWS to be protected by anodes,design life on request.

Ground anchors are made from high quality material and have sufficient design load.

All steel structures are checked by leakage test ,surface temperature,air environment,thickness checking, electric spark test, adhesion test etc.

Finished by intergard 954 paint, other paint brand are available. The dry film thickness is 300~500 micron on request.

Main Features:

· Manufactured from high quality plates and beams

· Steel structures are designed on basis of finite element analysis

· All welds are to be full penetration butt welds and continuous

·All steel structures are checked by leakage test ,surface temperature,air environment,thickness checking, electric spark test, adhesion test etc.

·Finished by intergard 954 paint, other paint brand are available. The dry film thickness is 300~500 micron on request. Gavanized is available.

Welded from high quality plates and beams, the Fender Panels(also known as Frontal Frame) are fitted front of fender,to increase the contacting area,reduce fender surface pressure to ship when the ships berth.

UHME PE face plate on the top of fender panel which has very small friction coefficient less than 0.12,greatly reduce the friction, molecular weight on request.

Steel structures are designed on basis of finite element analysis by our veteran engineer team,ensure the strength and life time.

All welds are to be full penetration butt welds, all fillet welds to be continuous,all exposed steel below MLWS to be protected by anodes,design life on request.

Ground anchors are made from high quality material and have sufficient design load.

All steel structures are checked by leakage test ,surface temperature,air environment,thickness checking, electric spark test, adhesion test etc.

Finished by intergard 954 paint, other paint brand are available. The dry film thickness is 300~500 micron on request.

Main Features:

· Manufactured from high quality plates and beams

· Steel structures are designed on basis of finite element analysis

· All welds are to be full penetration butt welds and continuous

·All steel structures are checked by leakage test ,surface temperature,air environment,thickness checking, electric spark test, adhesion test etc.

·Finished by intergard 954 paint, other paint brand are available. The dry film thickness is 300~500 micron on request. Gavanized is available.

Contact Us Now

Product Details

Fender Facing Panels

Welded from high quality plates and beams, the Fender Panels(also known as Frontal Frame) are fitted front of fender,to increase the contacting area,reduce fender surface pressure to ship when the ships berth.

UHME PE face plate on the top of fender panel which has very small friction coefficient less than 0.12,greatly reduce the friction, molecular weight on request.

Steel structures are designed on basis of finite element analysis by our veteran engineer team,ensure the strength and life time.

All welds are to be full penetration butt welds, all fillet welds to be continuous,all exposed steel below MLWS to be protected by anodes,design life on request.

Ground anchors are made from high quality material and have sufficient design load.

All steel structures are checked by leakage test ,surface temperature,air environment,thickness checking, electric spark test, adhesion test etc.

Finished by intergard 954 paint, other paint brand are available. The dry film thickness is 300~500 micron on request.

Main Features:

· Manufactured from high quality plates and beams

· Steel structures are designed on basis of finite element analysis

· All welds are to be full penetration butt welds and continuous

·All steel structures are checked by leakage test ,surface temperature,air environment,thickness checking, electric spark test, adhesion test etc.

·Finished by intergard 954 paint, other paint brand are available. The dry film thickness is 300~500 micron on request. Gavanized is available.

Welded from high quality plates and beams, the Fender Panels(also known as Frontal Frame) are fitted front of fender,to increase the contacting area,reduce fender surface pressure to ship when the ships berth.

UHME PE face plate on the top of fender panel which has very small friction coefficient less than 0.12,greatly reduce the friction, molecular weight on request.

Steel structures are designed on basis of finite element analysis by our veteran engineer team,ensure the strength and life time.

All welds are to be full penetration butt welds, all fillet welds to be continuous,all exposed steel below MLWS to be protected by anodes,design life on request.

Ground anchors are made from high quality material and have sufficient design load.

All steel structures are checked by leakage test ,surface temperature,air environment,thickness checking, electric spark test, adhesion test etc.

Finished by intergard 954 paint, other paint brand are available. The dry film thickness is 300~500 micron on request.

Main Features:

· Manufactured from high quality plates and beams

· Steel structures are designed on basis of finite element analysis

· All welds are to be full penetration butt welds and continuous

·All steel structures are checked by leakage test ,surface temperature,air environment,thickness checking, electric spark test, adhesion test etc.

·Finished by intergard 954 paint, other paint brand are available. The dry film thickness is 300~500 micron on request. Gavanized is available.

Contact Us Now:

-

ABOUT US

-

PRODUCT

-

NEWS

-

CONTACT US

ADDRESS:No.19 Qutangxia Road, Shinan District,Qingdao City,China

TELEPHONE:+86 0532 89922862

E-MAIL:sales@seakongmarine.com

NEWS

CONTACT US

ADDRESS:No.19 Qutangxia Road, Shinan District,Qingdao City,China

TELEPHONE:+86 0532 89922862

E-MAIL:sales@seakongmarine.com

.jpg)